Introduction

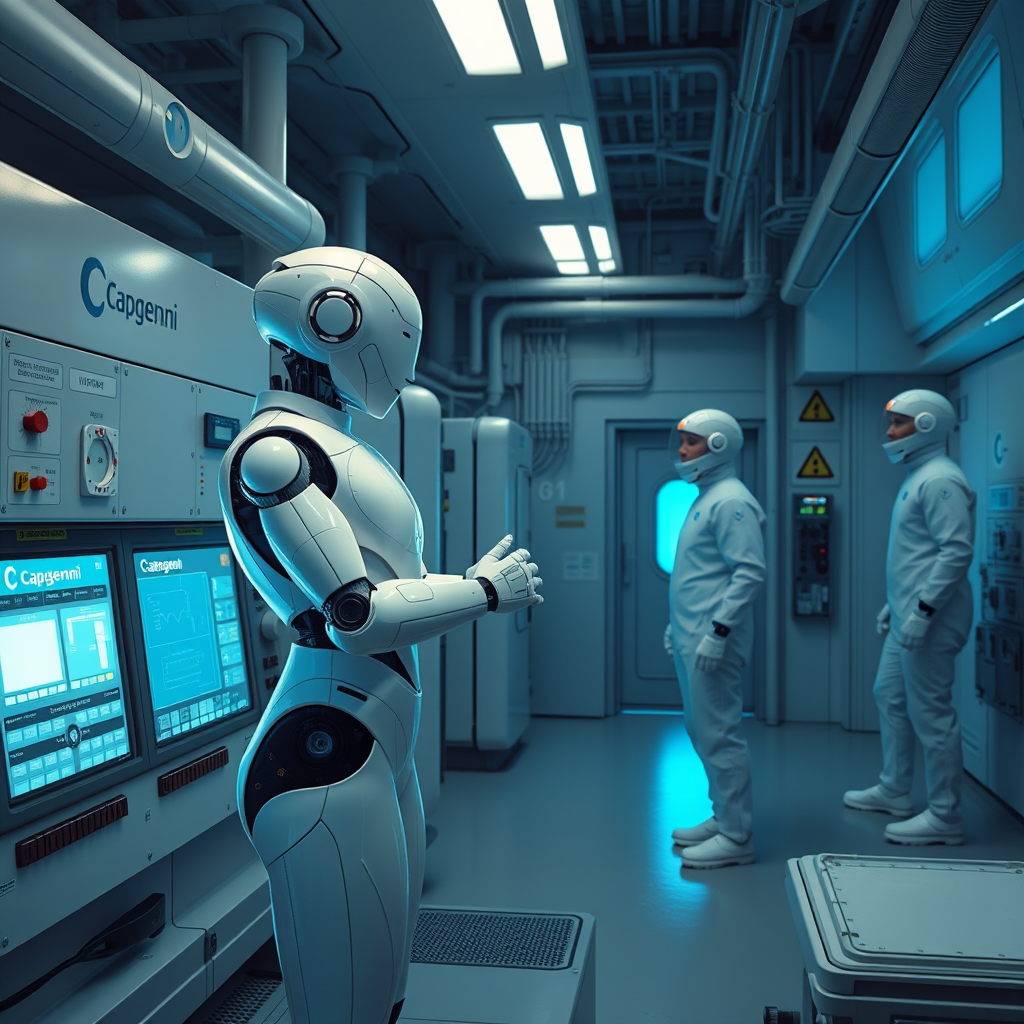

The deployment of a humanoid robot in a nuclear power plant marks a watershed moment for both the robotics industry and the broader field of physical artificial intelligence. In a partnership that brings together Capgemini’s deep expertise in AI and Orano’s long‑standing experience in nuclear technology, the first humanoid robot has been installed at a nuclear facility in France. This event is not merely a showcase of engineering prowess; it signals a new era in which autonomous systems can operate safely in some of the most hazardous environments on Earth. The implications are far-reaching: from reducing human exposure to radiation to enabling more precise maintenance tasks, the introduction of humanoid robotics into nuclear infrastructure could reshape operational protocols, safety standards, and even the economics of nuclear energy.

Historically, robots in nuclear settings have been limited to simple, highly specialized machines—often tethered, non‑humanoid platforms that perform repetitive tasks such as inspection or material handling. The leap to a fully autonomous humanoid platform introduces a host of novel capabilities: bipedal locomotion, dexterous manipulation, and advanced perception systems that can interpret complex visual and sensor data in real time. These features allow the robot to navigate the intricate layouts of a reactor containment building, manipulate tools with human‑like precision, and respond to dynamic changes in the environment—abilities that were previously the domain of human operators.

The significance of this deployment extends beyond the immediate operational benefits. It also represents a critical testbed for the safety and reliability of AI systems in high‑stakes contexts. By operating in a nuclear plant, the robot must adhere to stringent safety protocols, maintain fail‑safe behavior, and provide transparent audit trails for regulatory compliance. The success of this initiative could therefore accelerate the adoption of AI‑driven automation across other regulated industries such as aerospace, maritime, and even healthcare.

Main Content

The Technical Architecture of the Humanoid Robot

At the heart of the system is a sophisticated integration of hardware and software that enables the robot to perceive, decide, and act autonomously. The robot is equipped with a suite of sensors—including LiDAR, stereo cameras, and force‑torque sensors—that feed data into a perception stack powered by deep learning models trained on thousands of hours of annotated nuclear plant footage. These models enable the robot to recognize structural elements, detect anomalies, and localize itself within a highly dynamic environment.

On the decision‑making side, a hierarchical control architecture blends model‑based planning with reinforcement learning. The high‑level planner generates a sequence of waypoints and task goals, while a lower‑level controller translates these into joint trajectories that respect the robot’s kinematic constraints. Importantly, the system incorporates a safety monitor that continuously evaluates the robot’s state against a set of hard constraints—such as maximum joint torques, collision avoidance thresholds, and radiation exposure limits—ensuring that any deviation triggers an immediate safe‑stop or hand‑over to a human operator.

Human‑Robot Collaboration in a Nuclear Context

One of the most compelling aspects of this deployment is the emphasis on collaborative operation rather than full autonomy. While the robot can perform many tasks independently, it is designed to work alongside trained nuclear technicians, augmenting their capabilities rather than replacing them. For instance, the robot can carry out routine inspections of reactor internals, relay high‑resolution imagery back to the control room, and even manipulate tools under the guidance of a human supervisor.

This collaborative paradigm addresses a key concern in the deployment of AI in safety‑critical environments: the need for human oversight. By maintaining a clear interface for human intervention—through a user‑friendly dashboard that displays real‑time telemetry, status alerts, and a visual representation of the robot’s planned trajectory—operators can quickly assess the robot’s actions and intervene if necessary. This design philosophy aligns with the concept of “human‑in‑the‑loop” AI, which has become a cornerstone of responsible AI deployment in regulated industries.

Regulatory and Ethical Considerations

Deploying a humanoid robot in a nuclear plant inevitably raises regulatory questions. The French nuclear regulatory authority, ASN, has issued a set of guidelines that the Capgemini‑Orano team had to satisfy before the robot could be activated. These guidelines cover everything from radiation shielding to cybersecurity, ensuring that the robot’s software cannot be tampered with and that data privacy is maintained.

Ethically, the introduction of autonomous systems into nuclear facilities also prompts discussions about workforce displacement and skill requirements. While the robot reduces exposure to hazardous environments, it also necessitates new roles for technicians who specialize in robot maintenance, software updates, and safety verification. Capgemini has responded by investing in training programs that equip existing staff with the skills needed to manage and supervise the humanoid platform, thereby turning a potential threat into an opportunity for upskilling.

Future Implications for the Nuclear Industry

If the pilot proves successful, the next logical step would be to scale the deployment across multiple reactors, both in France and internationally. The ability to perform complex maintenance tasks—such as valve replacement, pipe inspection, and even emergency response—could dramatically reduce downtime and operational costs. Moreover, the data collected by the robot could feed into predictive maintenance models, allowing operators to anticipate equipment failures before they occur.

Beyond maintenance, the humanoid robot could also serve educational purposes. By providing immersive, real‑time visualizations of reactor internals, the robot could help train new engineers and technicians in a safe, controlled environment. This dual role—both operational and educational—underscores the transformative potential of physical AI when applied thoughtfully.

Conclusion

The deployment of Capgemini’s humanoid robot at a nuclear plant is more than a technological milestone; it is a proof of concept that autonomous systems can operate safely and effectively in some of the most demanding environments on the planet. By combining advanced perception, robust control, and a collaborative human‑robot interface, the project demonstrates that physical AI can enhance safety, efficiency, and resilience in nuclear operations. The success of this initiative will likely catalyze further investment in robotics across regulated industries, paving the way for a future where intelligent machines work hand‑in‑hand with human experts to tackle complex, high‑stakes challenges.

Call to Action

If you are a robotics enthusiast, a nuclear engineer, or a policymaker interested in the intersection of AI and safety, we invite you to dive deeper into this groundbreaking project. Subscribe to our newsletter for the latest updates on physical AI deployments, join our upcoming webinar where Capgemini’s lead engineers will discuss the technical nuances of the humanoid platform, and share your thoughts on how autonomous systems can shape the future of high‑risk industries. Together, we can explore the possibilities and ensure that the integration of AI into critical infrastructure is both responsible and transformative.