Introduction

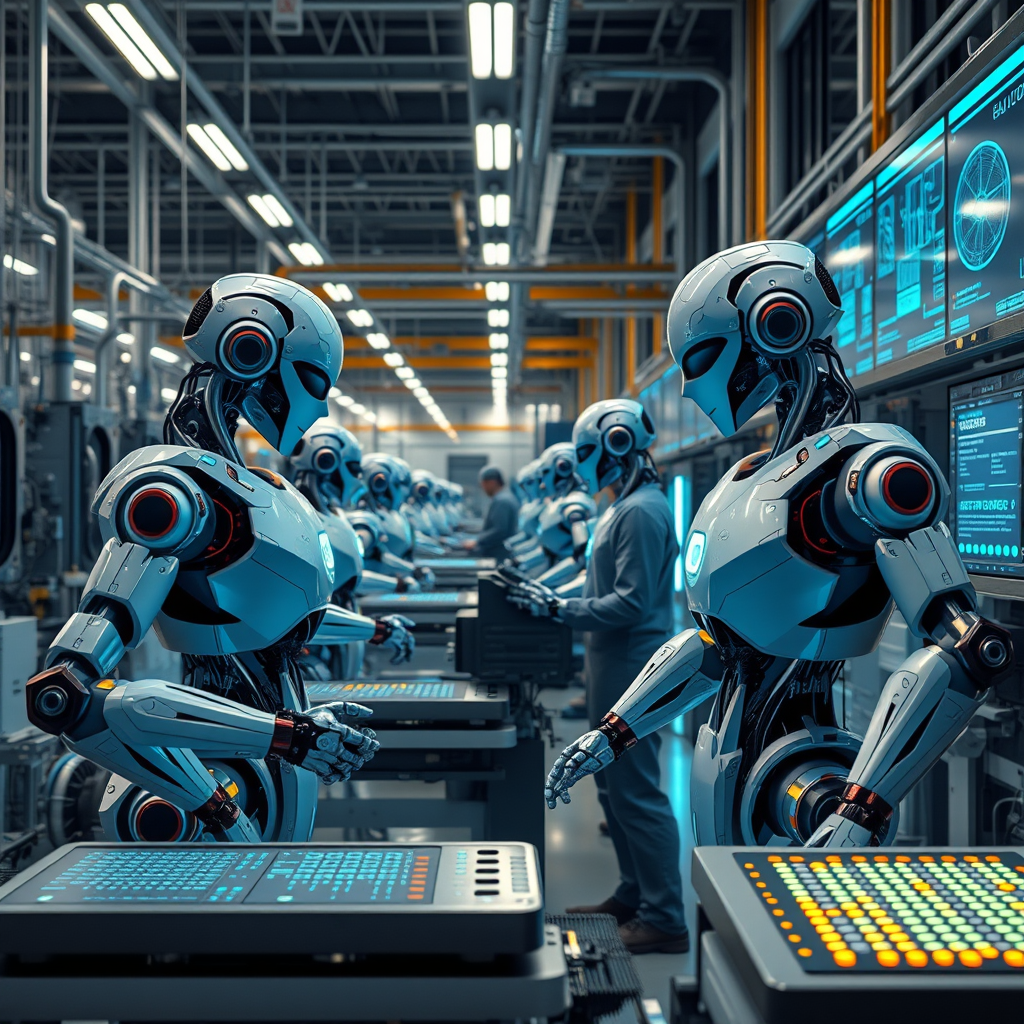

The manufacturing landscape is undergoing a seismic transformation that echoes the industrial revolution of the 1960s, yet it is powered by a different kind of technology: artificial intelligence. Where once factory floors were dominated by rigid, pre‑programmed machines that could only perform a single task with unwavering precision, today’s robots are learning, adapting, and collaborating in real time. Imagine walking into a production line and seeing a robot pause to inspect a component, adjust its grip on a fragile part, or reroute itself around an unexpected obstacle—all without human intervention. This is not a speculative vision; it is the new reality of AI‑enabled robotic autonomy. The shift from deterministic automation to intelligent, self‑optimizing systems is redefining what factories can achieve, from the speed of product iterations to the scale of customization. In this post we explore the core technologies driving this change, the tangible benefits manufacturers are reporting, and the broader economic and ethical implications that accompany the rise of thinking machines.

Main Content

Adaptive Problem Solving on the Factory Floor

Traditional industrial robots rely on exhaustive programming and a static environment to function. Any deviation—an off‑spec part, a shift in material flow, or a change in lighting—requires a new set of instructions and often a costly downtime. AI‑powered robots break this cycle by incorporating machine learning algorithms that can generalize from past experiences. By observing a human operator or a set of demonstration trials, these machines build internal models of how to handle a task under varying conditions. This capability translates into a dramatic reduction in setup time; where a conventional robot might need weeks to be re‑programmed for a new product, an AI‑enabled counterpart can learn a new task in hours or even minutes.

Learning Through Demonstration

One of the most compelling advances in robotic autonomy is the shift from code‑centric programming to demonstration‑based learning. Instead of writing line‑by‑line instructions, engineers now guide a robot through a sequence of motions, allowing the system to capture the nuances of human dexterity. The robot then uses reinforcement learning or imitation learning techniques to refine its policy, optimizing for speed, precision, or safety. This approach democratizes robot programming, enabling technicians with limited coding experience to deploy sophisticated automation solutions. Moreover, because the learning process is continuous, the robot can adapt to wear and tear, supply chain variations, or even new product designs without a full retraining cycle.

Enhanced Perception and Precision

Computer vision and sensor fusion have become the backbone of modern robotic autonomy. High‑resolution cameras, depth sensors, and force‑feedback actuators provide a rich stream of data that the robot’s neural networks process in real time. This sensory input allows machines to recognize objects under variable lighting, detect defects in components, and adjust their grip strength for delicate items such as electronic assemblies or soft food products. The result is a level of precision that rivals, and in some cases surpasses, human operators, all while maintaining the consistency and endurance of a machine. The integration of tactile sensors further expands the robot’s capabilities, enabling it to perform tasks that require a nuanced sense of touch—an area that has historically been a barrier to full automation.

Economic and Workforce Implications

The productivity gains reported by early adopters are striking. Pilot programs have documented 30–50% increases in throughput, reductions in scrap rates, and the ability to run smaller batch sizes without sacrificing efficiency. These improvements are not merely incremental; they enable manufacturers to pivot from mass production to a more agile, demand‑driven model. In an era where customization and rapid time‑to‑market are prized, AI‑enabled robots provide the flexibility that was previously only achievable at a higher cost.

However, the shift to intelligent automation also reshapes the workforce. While some fear job displacement, the reality is that new roles are emerging—robot supervisors, data scientists, and system integrators who bridge mechanical engineering and AI. The skill set required now includes an understanding of both the physical mechanics of the machine and the algorithms that govern its behavior. Training programs must evolve to equip workers with this hybrid expertise, ensuring that the human element remains a strategic asset rather than a liability.

Ethical and Governance Challenges

As robots gain the ability to make autonomous decisions, questions of accountability and safety become paramount. Who is responsible when an AI‑controlled machine produces a defective part or, more gravely, causes an injury? Manufacturers must develop clear governance frameworks that delineate responsibility across design, deployment, and maintenance phases. Additionally, safeguards must be built into the learning algorithms to prevent the robot from optimizing for efficiency at the expense of safety or quality. Transparency in decision‑making processes and rigorous testing protocols are essential to build trust among workers, regulators, and consumers.

Future Horizons

Looking ahead, several trends are poised to accelerate the adoption of AI‑enabled robotics. First, the concept of self‑optimizing factories—where robotic systems continuously refine their processes through reinforcement learning—will become mainstream, reducing the need for human intervention in process tuning. Second, advances in tactile feedback and soft robotics may unlock new applications in pharmaceuticals, food processing, and even surgical assistance, where delicate handling is critical. Third, the convergence of 5G, edge computing, and distributed AI will enable robots in disparate locations to share knowledge in real time, creating a networked ecosystem of learning machines that can solve complex, cross‑factory problems.

Conclusion

The rise of AI‑powered robots marks a watershed moment in manufacturing history. By blending physical dexterity with adaptive intelligence, these machines are breaking the constraints that once limited automation to repetitive, predictable tasks. The resulting gains in productivity, flexibility, and product quality are already reshaping supply chains and redefining competitive advantage. Yet the transition also demands a thoughtful approach to workforce development, ethical governance, and system design. As factories evolve from static production lines into dynamic learning ecosystems, the partnership between human ingenuity and machine intelligence will determine the trajectory of industrial innovation.

Call to Action

If you’re involved in manufacturing, supply chain, or industrial engineering, now is the time to explore how AI‑enabled robotics can transform your operations. Start by assessing which repetitive or high‑variation tasks could benefit from adaptive learning, and engage with vendors that offer demonstration‑based training platforms. Invest in upskilling your workforce to bridge mechanical and AI expertise, and establish clear governance protocols to manage accountability and safety. Share your experiences, challenges, and successes with peers and industry forums—collective insight will accelerate the adoption of this transformative technology and help shape the future of manufacturing for the better.